We’re experts here

- Use of all materials that can be cold formed: Stainless steel in A2 / A4 / A5 / A8 quality, steel in different qualities and strengths, special materials, bi-metal, aluminium, brass and much more.

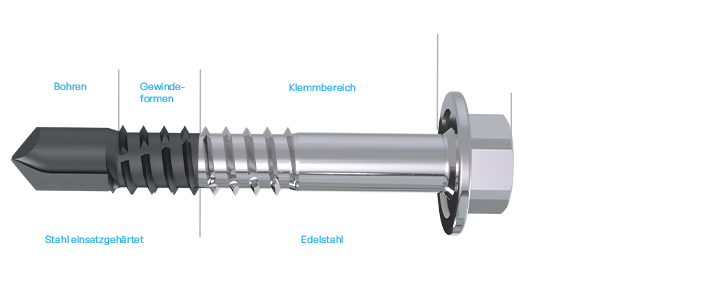

- A wide variety of heat treatments, surface treatments and surface coatings, tempering to 8.8/10.9, case hardening, inductive hardening, tempering

- Development of innovative products

- Development and implementation according to your requirements

- Customer-specific solutions from several components

Steel

Steel is a material consisting mainly of iron with a low carbon content, and a distinction is made between unalloyed (limited hardening properties) and alloyed steels (good hardening properties). Our steels are manufactured on the basis of our delivery specifications, which are based on DIN EN 10263-1 to -4 for cold-dip and cold extruded steels.

Stainless steel

Stainless steel has a high chromium content (min. 10.5 percent) and a carbon content of max. 1.2 percent. The chromium content forms a passive layer on the material surface that protects against corrosion and has a self-healing effect in the event of minor damage to the surface.

Other alloy components include nickel and molybdenum. They increase corrosion resistance. We only use austenitic stainless steels (A2 to A5), these being the main structural component of many stainless steels and non-magnetic. We recommend working with stainless steel screws outdoors.

Our competence - stainless steel

As an industry specialist in the manufacture of stainless steel screws, we manufacture quality products made of A2, A4, A5 and A8 stainless steel in accordance with the standards applicable to the respective applications.

The most common types of stainless steel used in connection elements are A2 and A4. Stainless steel A5 is used for more stringent requirements and stainless steel A8 for requirements involving high corrosion resistance (CRC V in accordance with DIN EN 1993-1-4).

These stainless steels are ideally suited for chlorinated and saline environments, whether indoors or outdoors.

STAINLESS STEEL A2/A4

The advantage of A2 and A4 stainless steel connection elements over C1 stainless steels is that they possess better corrosion properties. A4 screws in particular are ideal for use in salt water or acidic environments, as they are highly resistant in both cases. Typical areas of use are in the immediate vicinity of salt water.

STAINLESS STEEL HCR 1.4539

Stainless steel HCR 1.4539 is more resistant to corrosion and acids than A2 or A4 stainless steels. Connection elements made of HCR 1.4539 are used in atmospheres containing chlorine (for example indoor swimming baths) or by the sea where there is direct water splashing (jetties).

STAINLESS STEEL A8 1.4529

The stainless steel A8 1.4529 is a further development of the material HCR 1.4539 and is characterised by its particularly high resistance (CRC V) to local corrosion phenomena such as chlorine-induced cracking, stress corrosion or pitting. In addition, it has good polishing and mechanical properties and can be used in a wide temperature range. This is why the material is mandatory in the specific areas for fastenings used on load-bearing components.