A sea of 2.219 million REISSER thin sheet screws

In 2018, one of the largest combined metal roofs in the world was installed at Istanbul Grand Airport. The roof has no heat bridge mounting and was completed in a record time of just 20 months, using 425,000 m² of standing seam roofing and over 5 million screws and rivets.

The unique architectural design of Istanbul airport combines contemporary and functional elements that were inspired by the rich cultural heritage of the city, drawing on its colours, patterns and history. The vaulted ceiling features skylights to let in diffused daylight, creating a spacious design with clear sight lines.

To plan and implement the roof building project, BEMO systems, based in Ilshofen, Germany, collaborated with ADEN Metal, based in Istanbul. All of the sheet metal panels were produced on-site using portable roll formers. Both the steel support structure and the aluminium cover sheet were made using BEMO standing seams. The entire roof was installed in record time thanks to over 1000 construction workers installing sections of the roof at a rate of between 40,000 and 50,000 m² per month. During construction of the roof, the teams used over 1800 tonnes of aluminium, over 6000 tonnes of steel, over 80,000 cbm of insulation, over 20 km of guttering, over 460 skylights and over 5 million fastening elements. REISSER Schraubentechnik GmbH supplied 2.219 million RP-T2-6.0x38 E16 thin sheet screws that had been specifically developed for this huge project.

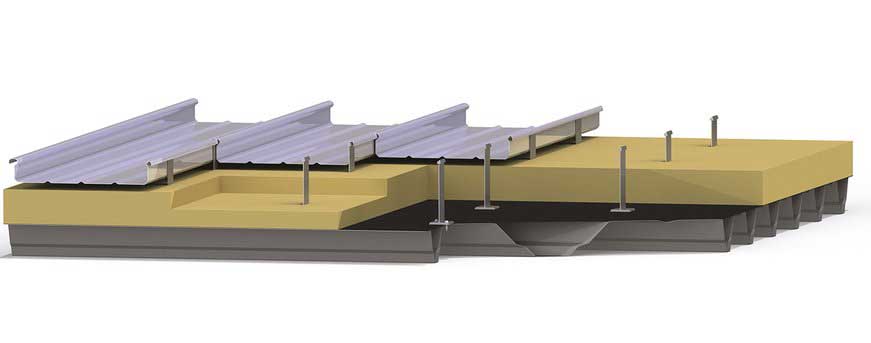

The RP-T2-6.0x38 E16 thin sheet screws supplied by REISSER are particularly advantageous when it comes to fixing standing seam clips to trapezoidal steel substructures. Buildings like airports are subject to very high air turbulence, resulting in dynamic pressure affecting the roof — this makes it essential to choose building materials and fasteners of the highest quality.

The RP-T2-6.0x38 thin sheet screws used in this project have technical approval for use with aluminium or glass-fibre reinforced plastic (GFRP) standing seam clips and are suitable for screwing these components onto trapezoidal steel substructures. The head and shaft of the screw are made from A2 stainless steel, while the tip is made from hardened carbon steel: Using two materials in this way creates a durable and corrosion-resistant bi-metal screw.

Thanks to "flow drill" technology, instead of removing material to form holes in the substructure, as is the case for conventional drilling screws, the material is simply reshaped. This method means there is more material for the thread to grip, and the higher the number of threads, the better the holding force and the greater the shear strength and the force required to pull out the screw. The resulting loads can dissipate safely across the substructure using a relatively low number of fasteners.

Another advantage is that no chips are formed when the drilling screws are drilled into the roof structure, so no time-consuming cleaning is required. This also means that there is no danger of chips damaging the sensitive vapour barriers. This chip-free design means that a source of corrosion is removed during the construction stage. This has the potential to save a lot of time for buildings the size of Istanbul airport, and also reduces the amount of reworking required.