Cleat attachment re-imagined

The conventional method of using adhesives to fasten standing seam profiles (panels) involves nailing.

Practical experience clearly shows that this processing method is not yet fully developed and can repeatedly lead to problems that require reworking. Our solution to the cumbersome handling with pneumatic nailers and the recurring need for reworking due to protruding nails is the adhesive screw.

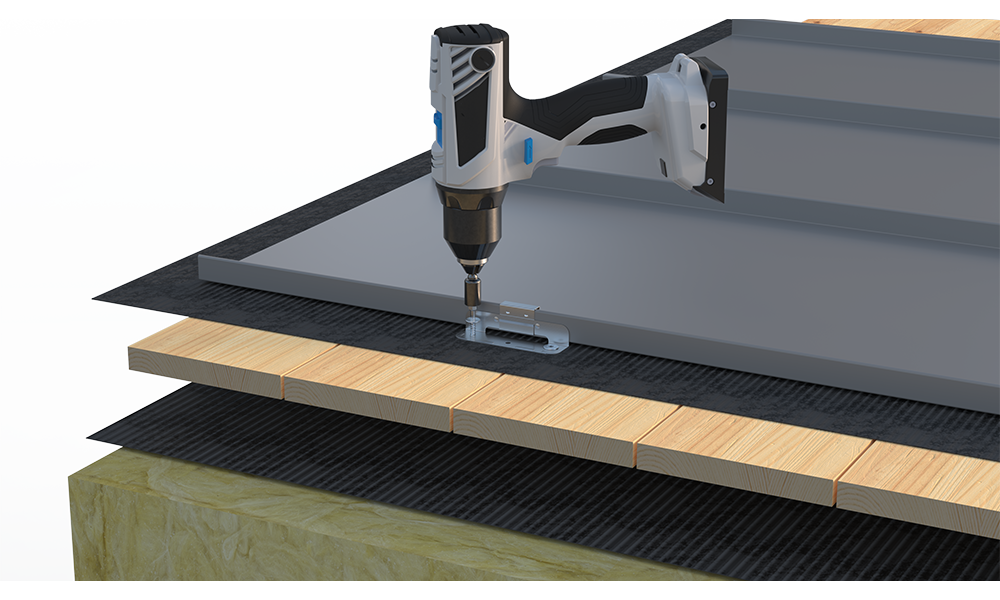

Our screw variant offers numerous advantages over conventional nailing. Easy handling with a cordless screwdriver ensures convenient installation with little effort and secure fastening at the same time. By eliminating the need for reworking, both time and money can be saved.

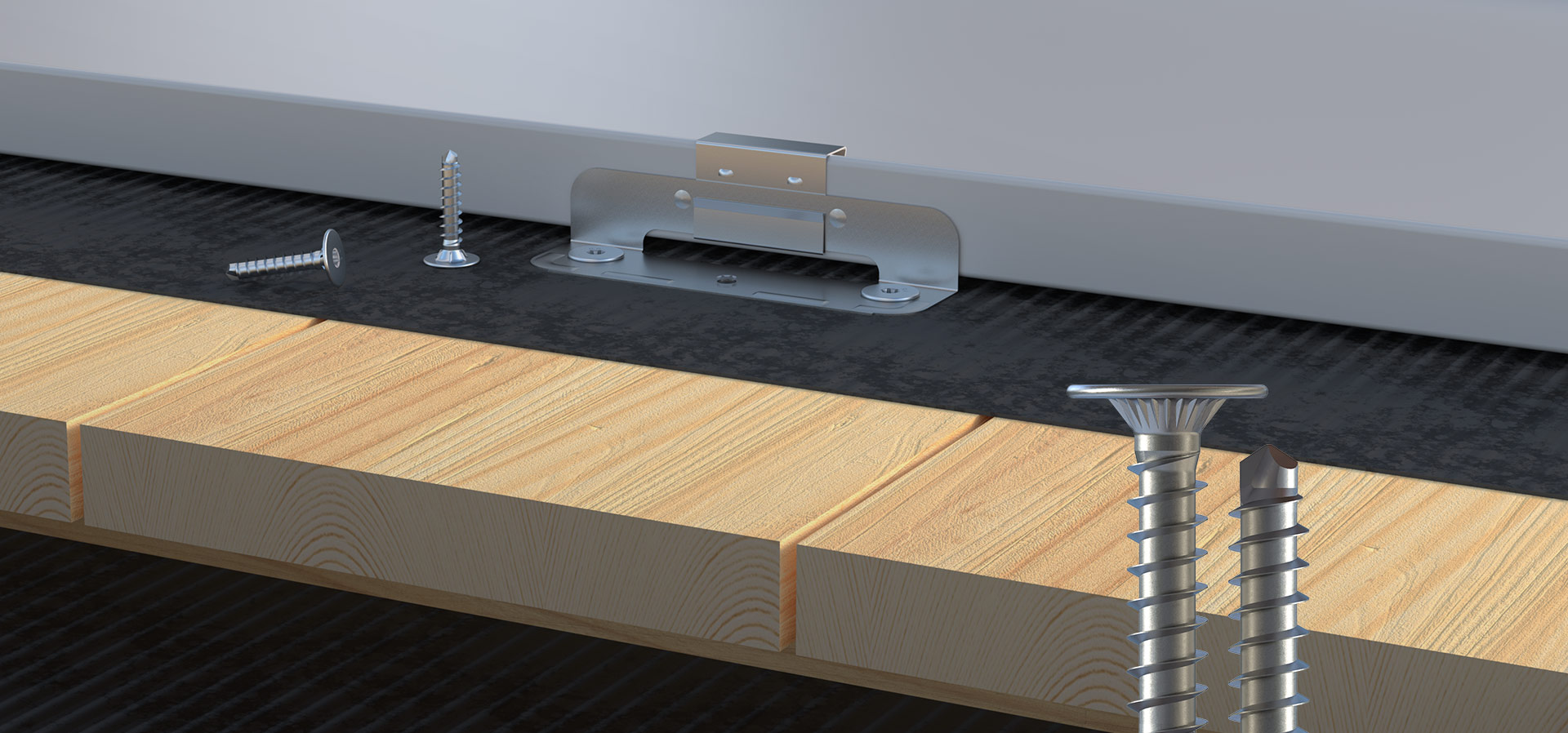

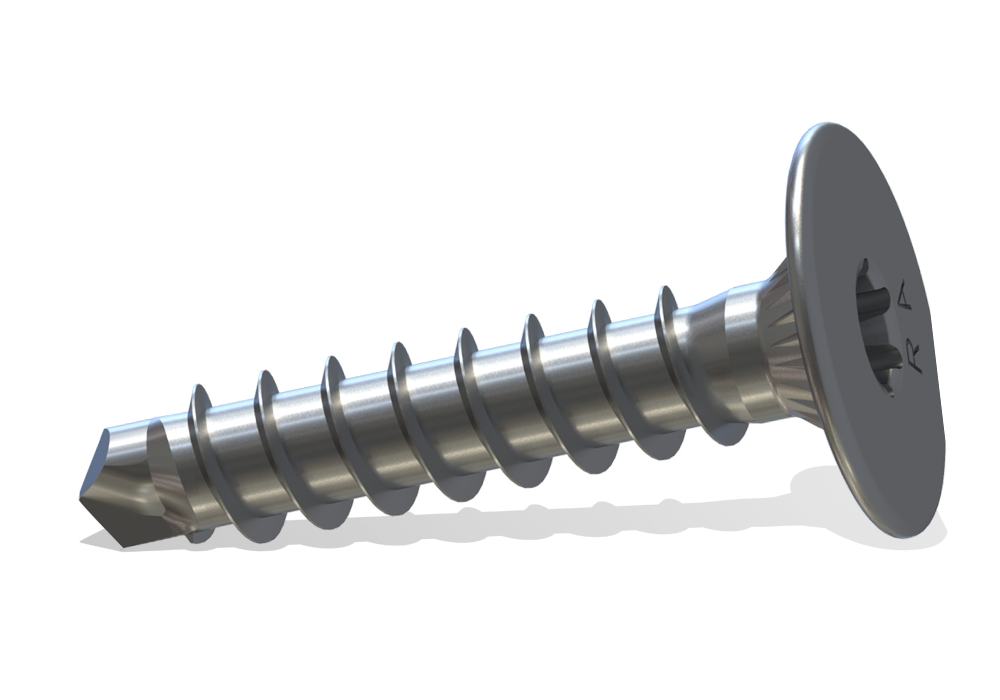

The adhesive screw is ideal for fastening adhesives to various substructures. We offer a wood and sheet metal version to meet the individual requirements of your various projects.

CONVENTIONAL PROCESSING

PROBLEM: PROCESSING RING-SHANK ROOFING NAIL

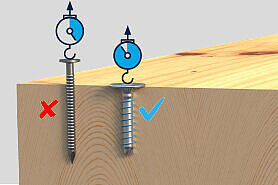

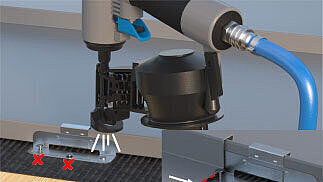

When inserting ring-shank roofing nails using a pneumatic or gas-powered nailer, the nail often ends up positioned incorrectly in the cleat hole. The nail may not be straight or it may protrude some distance from the metal cleat, preventing the standing seam profile from gliding smoothly over the cleat and thus causing wear.

DIFFICULT TO HANDLE

Practical experience clearly shows that even the most convenient, collated processingsolutions are proneo failing on a frequent basis.What's more, these devices are significantly

heavier than a cordless screwdriver. Pneumatic nailers also require a compressor and a compressed air hose, both of which are difficult to manage while working on a roof.

RE-WORKING – POSITION CANNOT BE CORRECTED

Another step is required to hammer any protruding nail heads flush to the cleat. This re-working costs time and therefore money.

If an incorrectly positioned cleat needs to be removed, the process of removing the nail with the framing hammer often destroys the cleat, requiring it to be replaced.

THE REISSER METHOD - RELIABLE AND CONVENIENT

PERMANENTLY SECURE FASTENING – ALSO SUITABLE FOR POSITION CORRECTION.

Thanks to its flat, rounded head, the REISSER cleat screw enables wear-free sliding of the standing seam profiles. In contrast to the cleat nail, the screw-in method ensures that the large screw head is permanently flush with the cleat – no reworking required.