SIMPLY QUICK

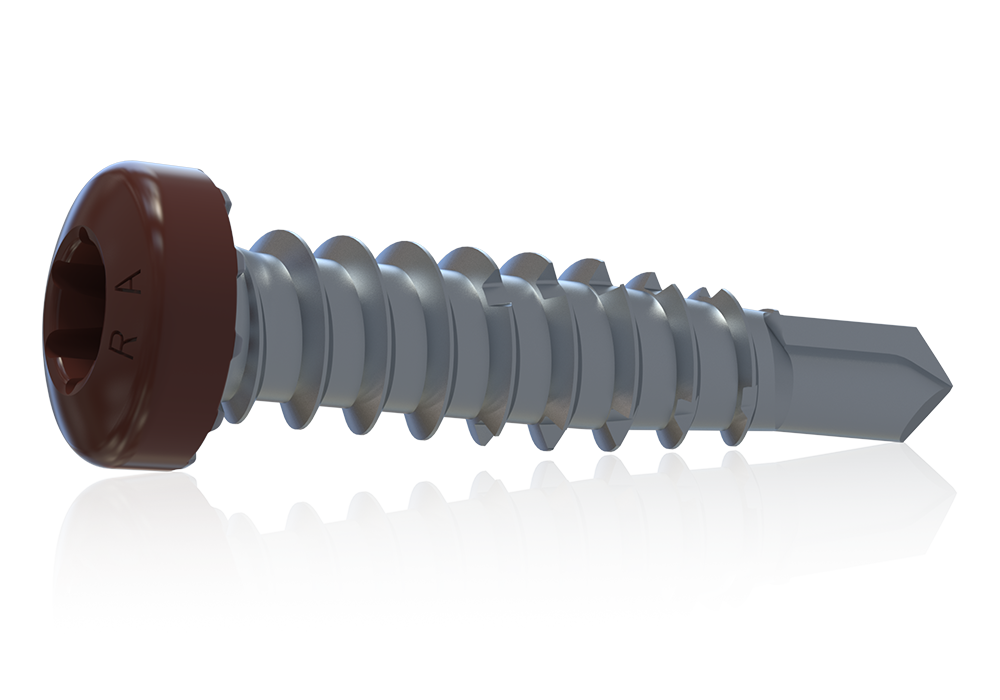

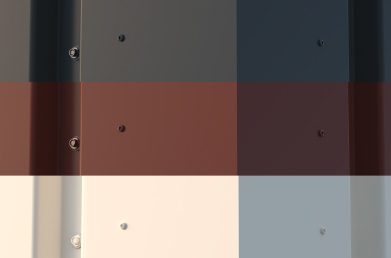

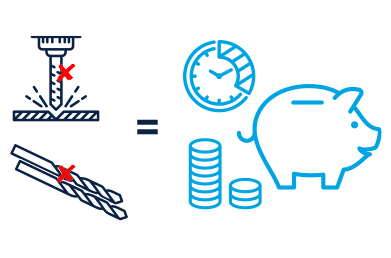

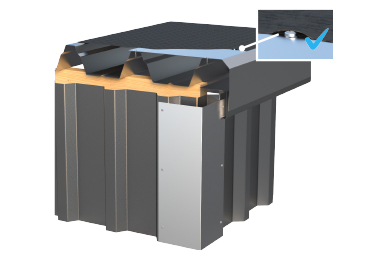

Are you tired of spending hours attaching rivets? Then we have the solution for you! With our folded part screw, we say 'no more rivets' and offer you an efficient alternative. Find out more about how we fasten flashings and discover how you can save time and effort. Let's work together to find a faster and more effective way of fastening flashings!

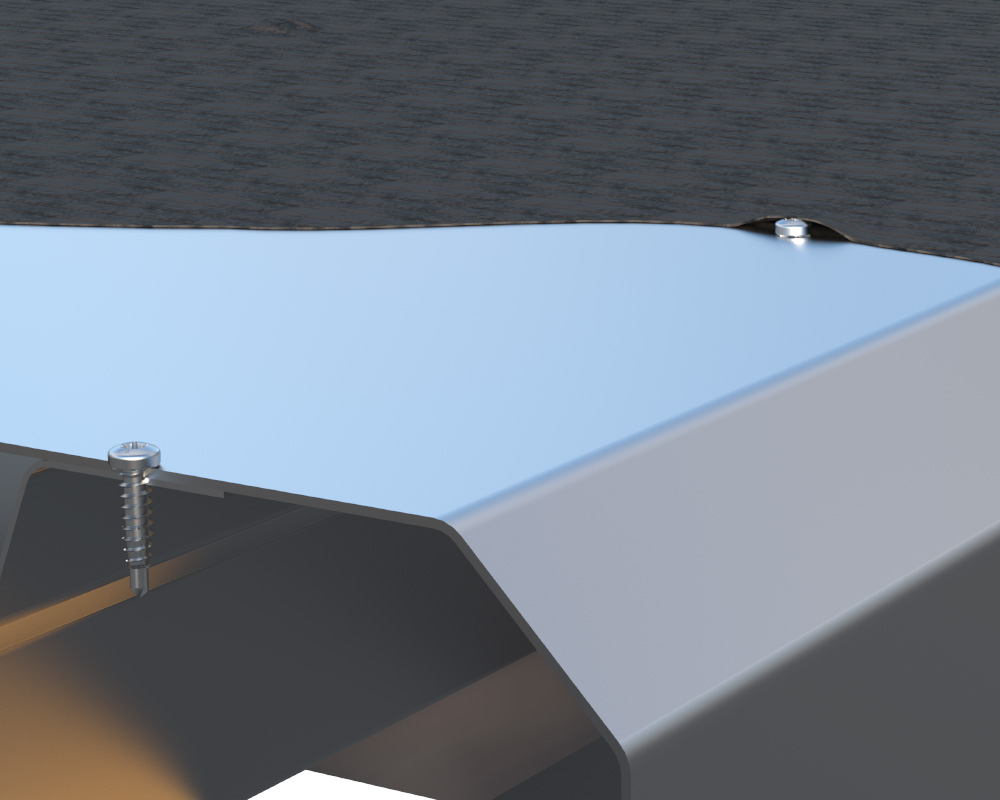

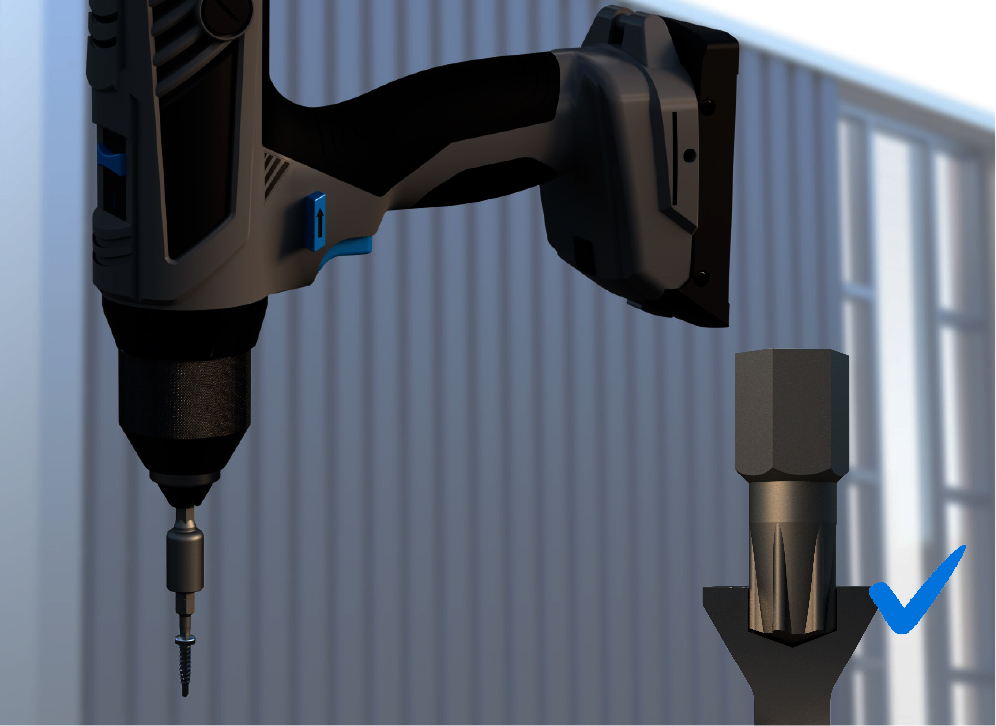

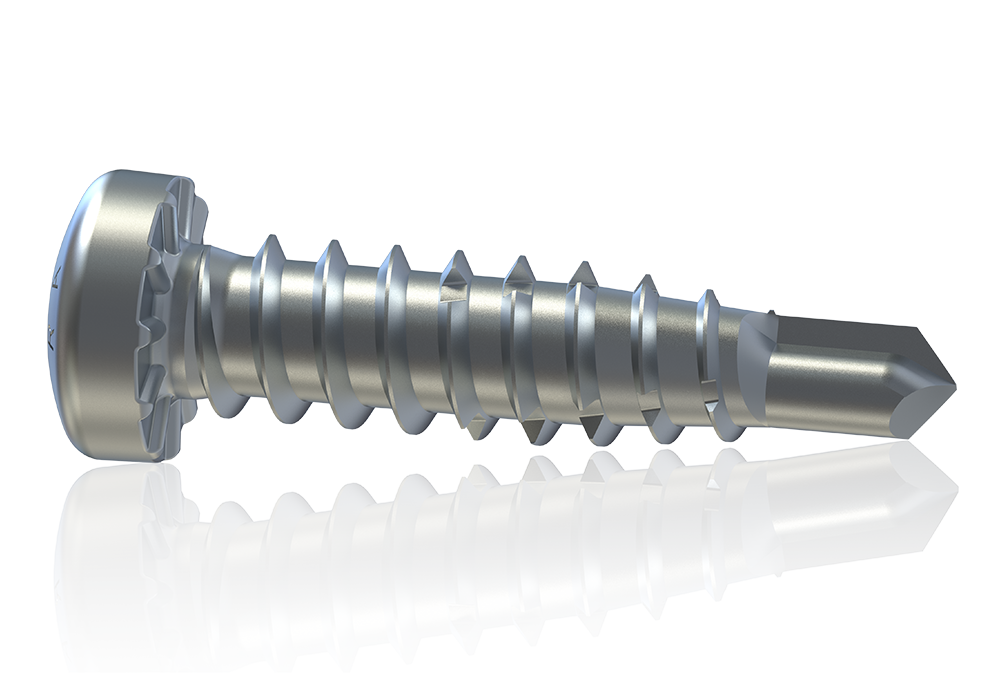

Sharp-edged drill tip prevents the drill from running off-centre during the drilling process compared to a conventional drill that has already completed several drilling operations. Unlike riveting, the recoil-free processing prevents scratches and dents to the building. What's more, the locking serration beneath the crew head makes it much more difficult to overtighten in thin sheet metal.

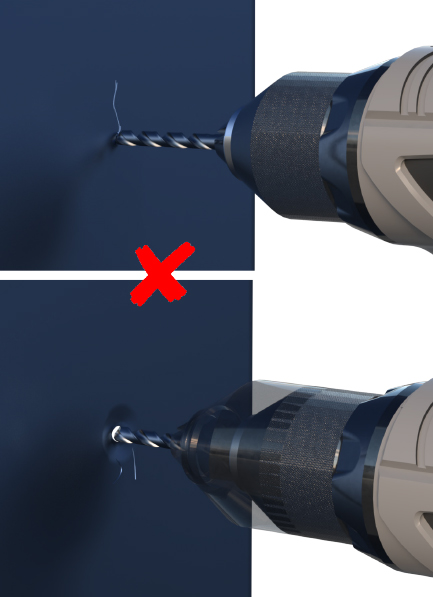

PRE-DRILLING CARRIES RISK

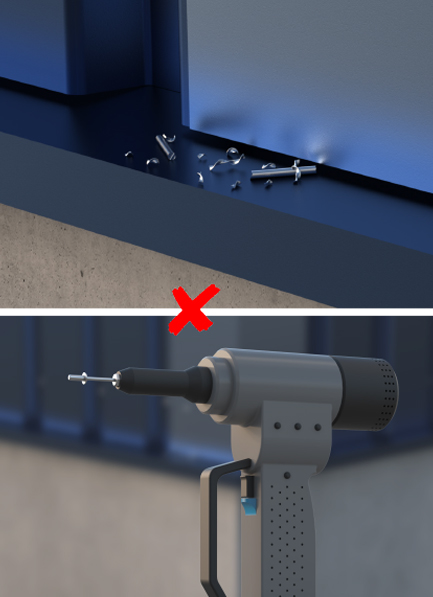

Multiple drilling processes wear tools out and leave them blunt. There is a high risk of the drill bit wandering and damaging the edge part.

The drill chuck may also contact the edge part during pre-drilling and cause a dent. It would then be necessary to repair or replace the edge part.