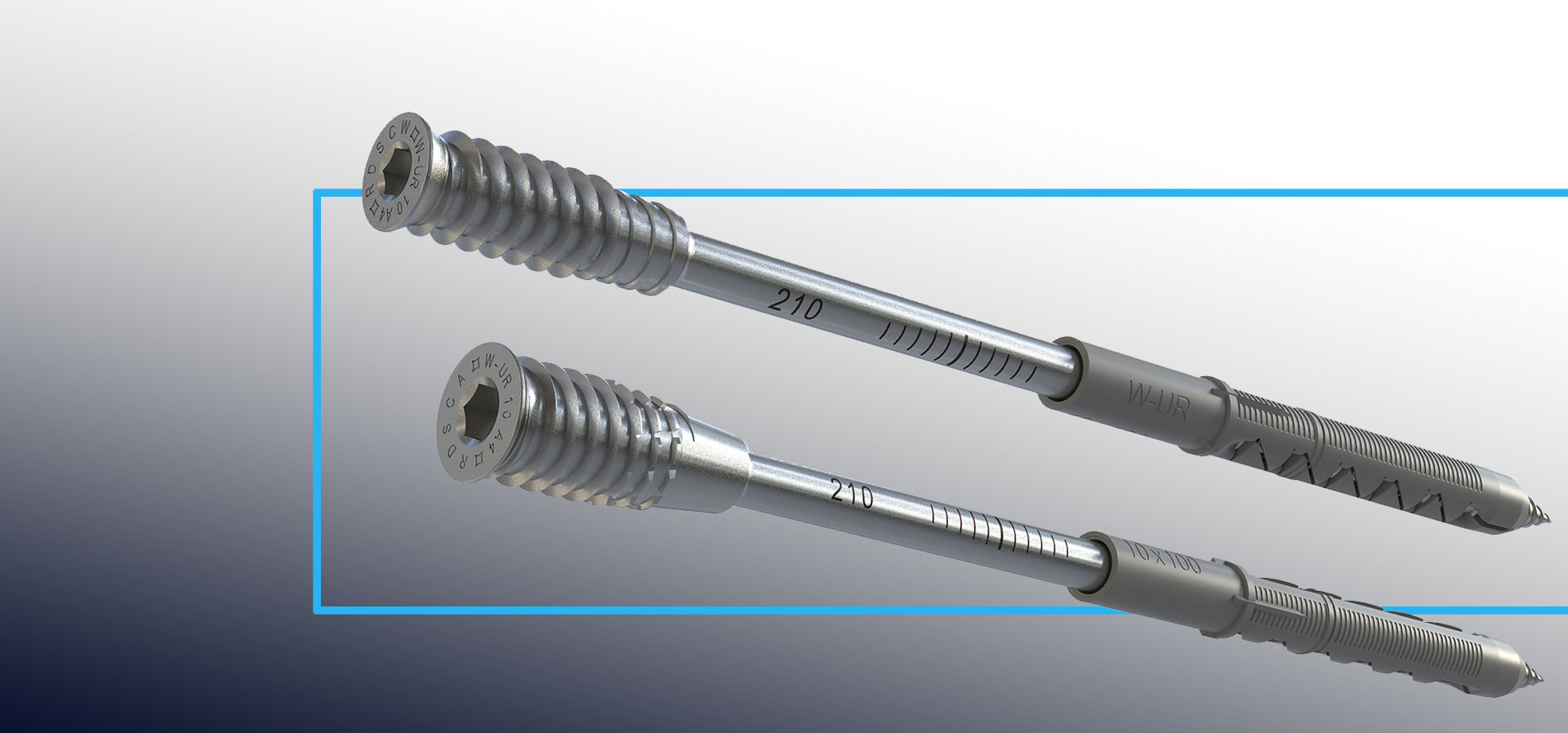

THE SECURE AND FLEXIBLE INSTALLATION SOLUTION

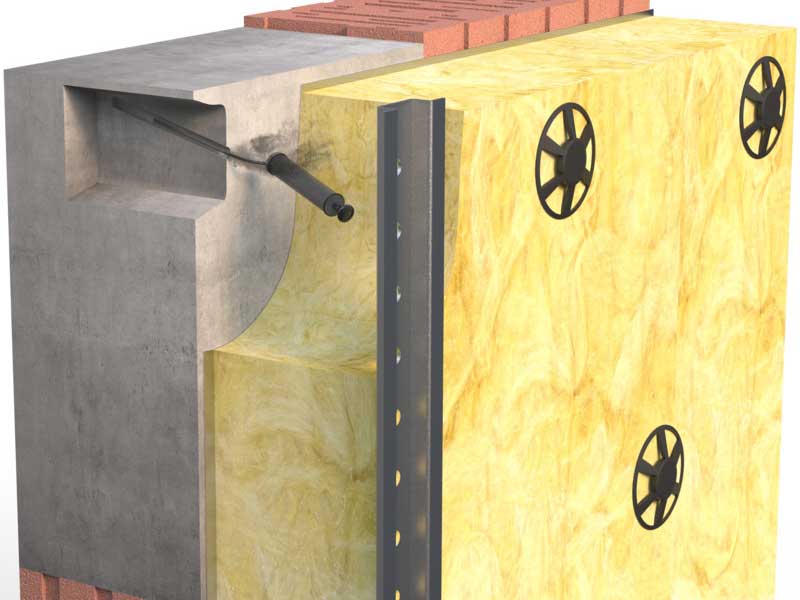

The REISSER spacer screw system is an installation-friendly, flexible VHF fastening solution that has been granted full technical approval. Its extremely low thermal conductivity means that the system is for the most part free of thermal bridges. In addition, our fastening solution fulfils all current fire protection requirements for VHF.

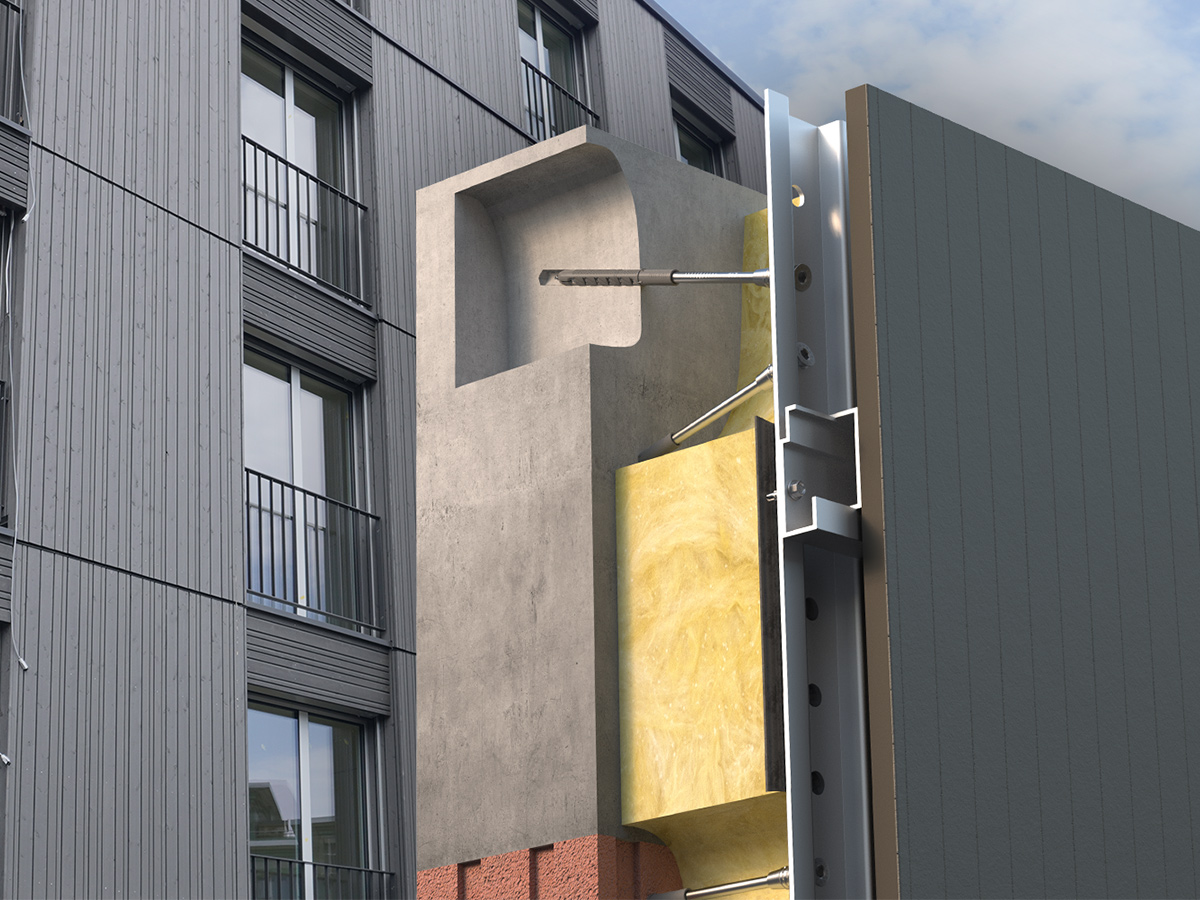

Optimum load transfer

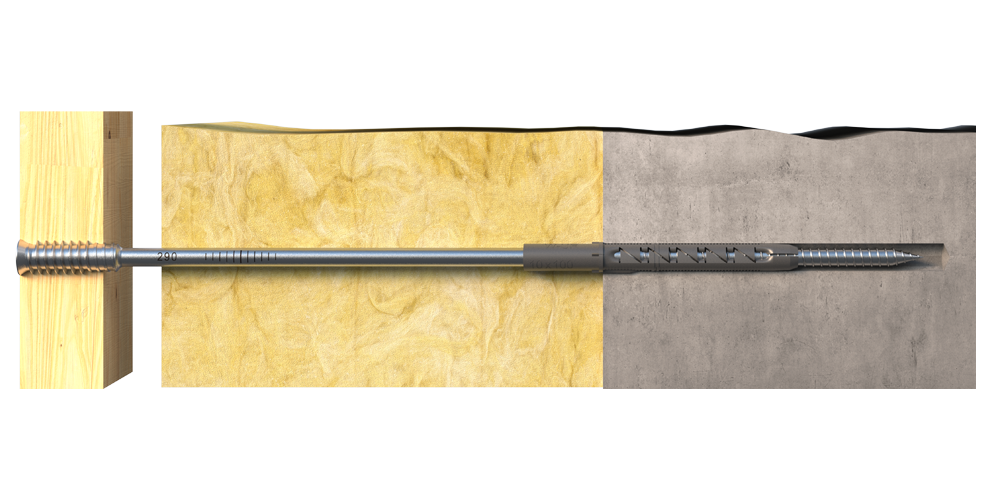

Timber house framework screw connection

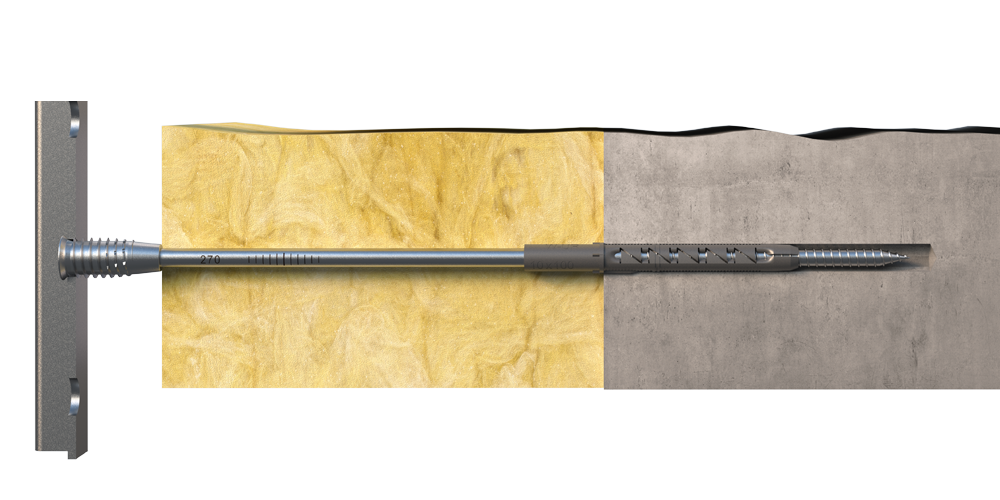

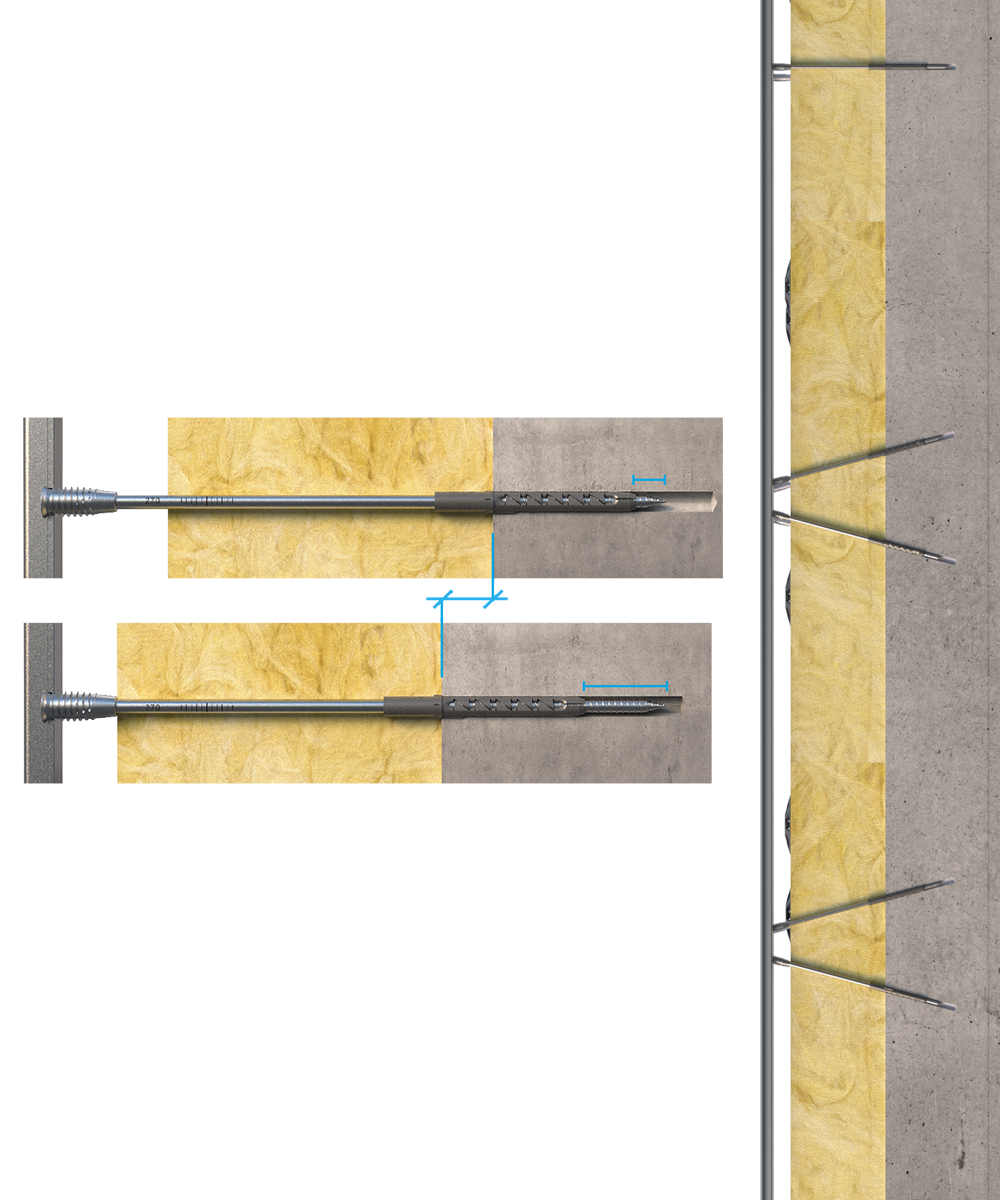

Excellent transfer of the facade load (facade weight & wind load) via the spacer screw with anchor into the masonry/concrete, with both weak and pressure-resistant insulation.

Compensation of masonry tolerances

Perfect compensation of masonry tolerances of up to 25 mm.

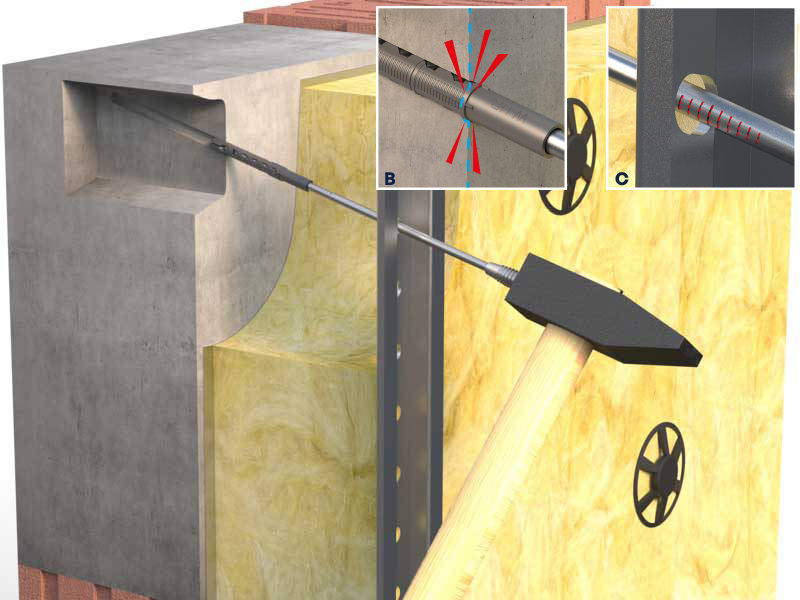

The construction can also be easily aligned afterwards. The profile can be readjusted at any time by turning back the 0° screw and then screwing the screw back in. The final position should be reached before the 15° screws are set.

Slowly screw in (approx. 100 rpm) until the end position in the profile is reached (the head thread must be positioned in the last third of the aluminium profile. The head must not fit closely, as there is a risk of shifting the position of the profile and weakening the fixing in the aluminium. In the wood version, the screw head is flush or countersunk into the wooden batten by maximum 2 mm).